Download Specifications Here

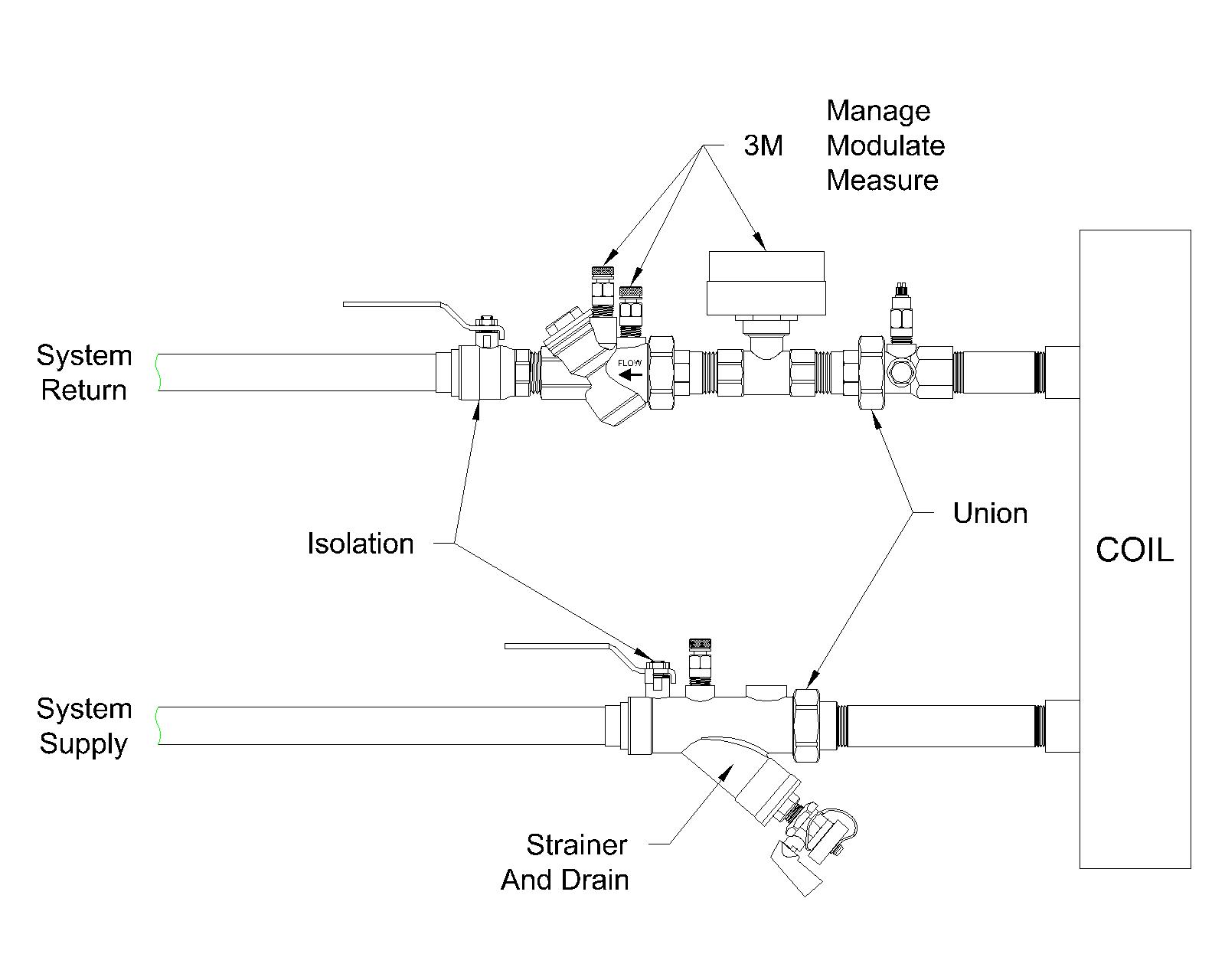

Automatic Flow Limiters

- Shall have the capability to measure flow. If other designs cannot measure flow with one unit, a separate low energy loss, flow measuring venturi shall be incorporated on the outlet side of the automatic flow limiter.

- Shall have setter valve functionality to allow for control valve stroke optimization.

- Automatic flow limiting cartridge(s) will be made of stainless steel. No brass or plastic components allowed.

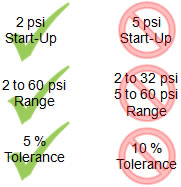

- Flow rate accuracy will be +/- 5% of design flow rate.

- Shall be of a pressure independent, clog resistant design.

- Valve cartridge shall have a single spring range of 2-60 psid, up to ASHRAE recommended maximum GPM.

- The flow rate (GPM) shall be factory preset and not field adjustable.

- Cartridges shall be easily removable from valve body without disturbing existing piping.

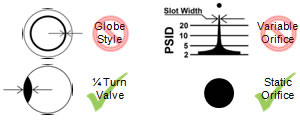

Manual Calibrated Balancing Devices

- A 15° regain chamber shall be integral to the design for minimal permanent pressure loss.

- Flow rate accuracy will be +/- 3% or better.

- Venturi shall be not be pressed in.

- Device shall incorporate a fully featured venturi design. Fixed orifice plates, calibrated ball valves or truncated venturi designs will not be accepted.

Wye-Strainers

- Strainers shall have a 20 mesh rating. Strainers with a lower mesh rating shall not be accepted.

- The strainer screen shall be constructed of stainless steel.

- The strainer screen shall have at minimum an 8:1 ratio of total area vs. internal pipe diameter.

- The strainer body shall incorporate a full-port isolation ball valve for minimum pressure loss. Standard or reduced port ball valves shall not be accepted.

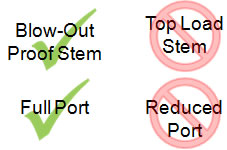

Valves

- Shall have a full-port ball.

- Shall have a blow-out proof stem.

- Ball shall be chrome plated.

Stainless Steel Braided Hoses

- One end connection shall swivel to allow for equipment movement during operation.

- ½” – 1” shall be made of CPE (Chlorinated Polyethylene).

- 1-¼” – 2” shall be made of EPDM (Ethylene Propylene Diene Monomer).

- Maximum working pressures:

- 500# WPSI Static (½” – 1”)

- 200# WPSI Static (1¼” – 2”)

- Maximum temperature rating: 212°F

- Hoses shall incorporate stainless steel ferrules.

Why Specifications are Important! | |

Specifications are important because, they not only communicate clearly what the Engineer allows during construction but, possibly even more important, specifications restrict what the Engineer does NOT allow during construction. Simply listing a manufacturer is not sufficient. Many manufacturers have a higher end product line that engineers are confident in along with some lesser designs to keep cost down. Engineers may not find the lesser designs acceptable. |

|

| For isolation, while an engineer might name certain suppliers as “allowed” based on reviews of samples fitting such criteria as Full Port Designs and Blow-Out Proof Stems, these same manufacturers also provide Reduced Port designs and others provide top load stems. Simply naming the manufacturer based on submitted samples does not mean that is what the contractor provides. The specification along with naming the manufacturer is now required to assure proper design. |

Strainer mesh has long been submitted as 20 mesh and is a normally accepted standard. However, many suppliers now default to 10 mesh which allows larger debris to pass that is particularly harmful with low flows at higher pressures. And if a High Efficiency Strainer is desired to minimize maintenance while assuring a system is clean, the surface area must be defined to assure the proper product is used and not a low end economy strainer. Small strainers are detrimental to a system! |

|

| While many suppliers provide products that can work in some situations, not all supplier’s products work in ALL situations. Low flow conditions are particularly sensitive with Manual Balancing Valves. A quarter turn valve with a venturi will help assure the product does not fail due to the Strainer Effect as a Multi-Turn valve will at low flow. Once the flow orifice is smaller than a strainer, the balancing valve becomes the strainer!! |

Automatic Flow Limiting Valves are probably the most “me too” product there is. Most of the suppliers will say they all perform the same or as good as one another. Stainless steel wear surface is critical. Brass will wear in just a few years. 5% flow tolerance is critical in energy management. If only comfort matters, the flow tolerance is not so critical but the start-up pressure is always critical when energy savings matters. Cartridges that are rated for 5 psi start-up that do no start up until 7 – 10 should not be allowed. Always use a 2psi rated start-up. Most of the premier suppliers provide products with at least a rated start up of 2 psi. Start up ratings of 5 psi and above introduce performance risks into the system. ALWAYS BE ABLE TO MEASURE FLOW! |

|