Why Use PRO Hydronic’s CBV?

Model CBV

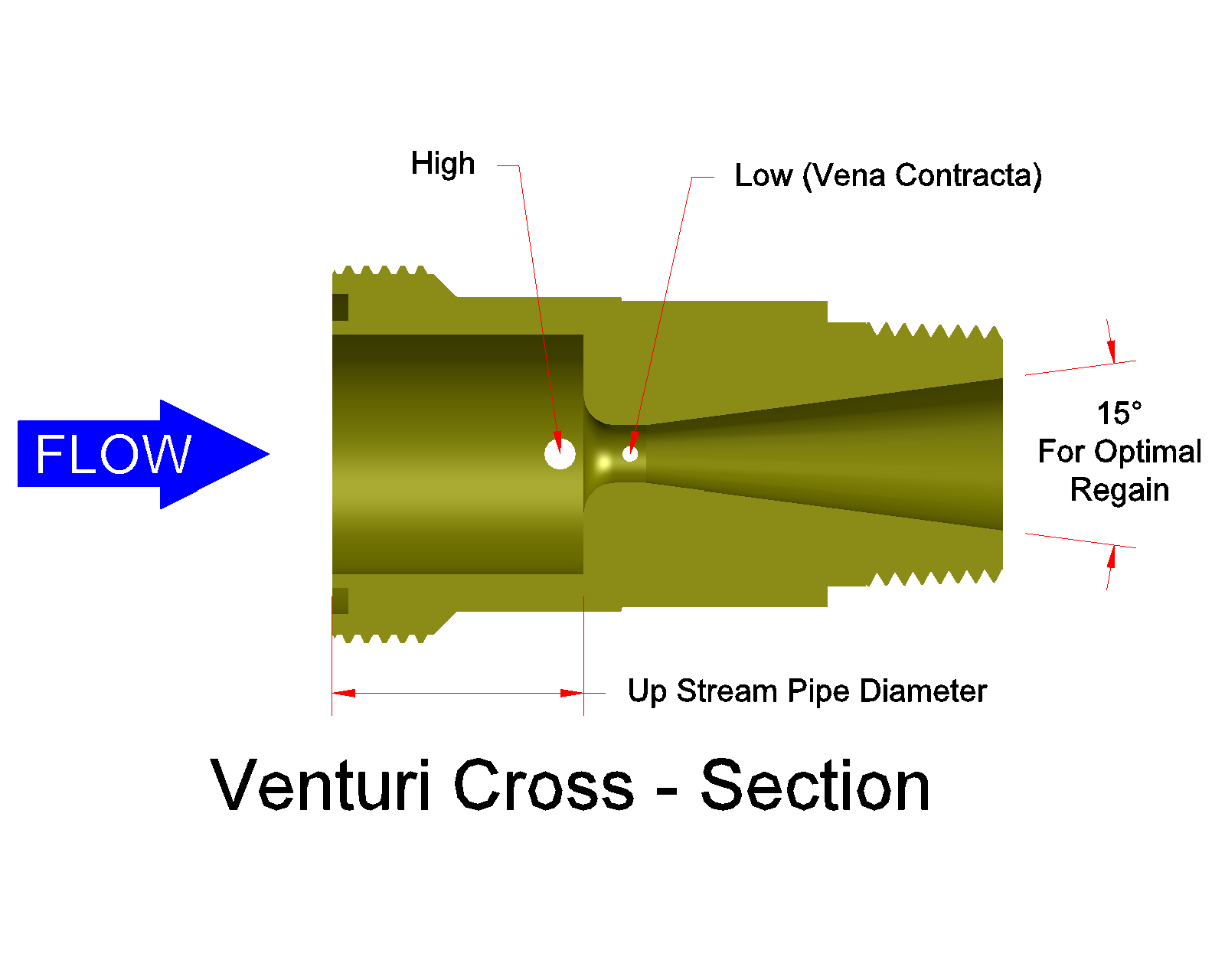

Following the PRO Hydronic Specialties’ philosophy of “Physics First” designs, our full line of manual balancing venturis are some of the most efficient and easy to commission manual balancing devices in the industry. Our designs incorporate features such as proper regain angle and length for low energy loss. Additionally, we have integrated the proper upstream pipe diameters needed for smooth flow and optimal accuracy.

Also available as a lead free option.

Why a Venturi with ¼ Turn Valve?

Strainer Effect on Low Flow Manual Balancing Valves

The illustration below demonstrates orifice sizes are often very small for low flow balancing valves. Due to design, the gap from the globe or disk design is smaller than the 20 mesh opening of the strainer for low flow requirements. PRO Hydronic Specialties utilizes a ¼ turn valve which allows optimal orifice size for a manual balancing valve under low flow conditions.

This is supposed to be the statement just below the advantage/disadvantage chart where it says Why a venturi.

How easy is it to limit flow? Easy as 1, 2, 3!

No calculator wheels or guessing required!

- Determine the differential pressure in Inches W.C. (pre-printed on tag, Flow Rate Table, or by equation).

- Attach a differential pressure gauge.

- Close the valve until the desired differential is achieved.

- Set the memory stop to limit full open if preferred.

Features and Benefits

- Extremely low energy loss

- Flow measurement inherent to design

- +/- 3% accuracy rate

- Memory stop included

- Available in MPT, FPT, and SWT connections

- Includes (2) ¼ Pressure/Temperature Ports

- Factory calculated In. W.C. printed on each tag for quick and easy commissioning

- Forged construction for:

- Tight tolerances

- Impeccable Accuracy

- Smooth, laminar flow

Applications

- Air Handlers

- Fan Coil Units

- Chilled Beams

- Cooling Towers

- Water Source Heat Pumps

- Chillers

- VAV HW Coils

- Unit Ventilators

- Hydronic Heaters

- Devices shall have a 15° regain chamber for optimal pressure regain and minimal permanent pressure drop

- The Venturi tube shall be independent of the throttling valve

- The Venturi tube shall include proper pipe diameters for optimal accuracy

- The valve shall be designed with a memory stop to limit flow once balanced

- The Model CBV shall have an accuracy rating of:

- +/- 1% between 10” W.C. and 70” W.C.

- +/- 3% between 5” W.C. and 150” W.C.

- +/- 5% less than 5” W.C. and over 150” W.C.

Manual Balancing Valves Product Sheet

The PRO Hydronic Advantage

Type of Orifice | Advantages | Disadvantages |

| Calibrated Variable Orifice |

|

|

| Orifice Plate |

|

|

| Truncated Venturi |

|

|

| PRO Hydronic’s True Venturi |

|

|